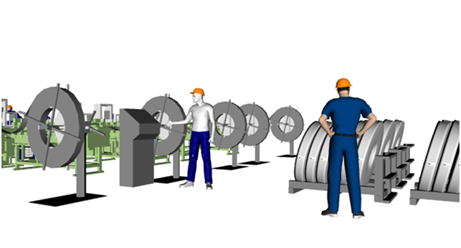

In order to control the rolling strips and the delivery of the pipe packages in close proximity of the mills it is required to install stationary terminals by means of which the mill operators could account the strips released into production and the delivery of pipe packages. The stationary terminal also can print self-adhesive labels for the packages.

Stationary terminals are positioned for the convenience of the mill operator to perform the registration of the packages and the release of the strips.

The supply of the tapes on the welding site is performed based on the production task that is delivered to the terminal from 1C.

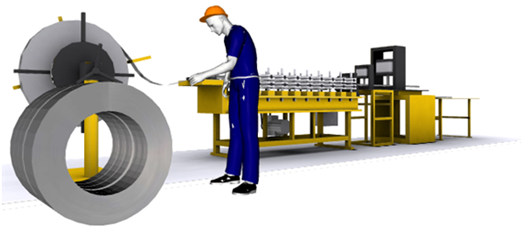

According to the task the mill operator takes the strips (strip production warehouse) specified in the task and moves it to the strip mill charging zone with a crane.

To start the rolling of one strip the mill operator detaches the tag with the barcode attached to the strip, and brings it to the reader of a stationary terminal. After scanning the bar code, the information that shows what strip is installed on the uncoiling machine is displayed on the screen of the stationary terminal.

The operator starts the strip rolling mill for production. Strip is lifted with a crane and placed on the uncoiling machine. The mill operator tears off from the strip the second part of the coupon tag, reads the bar code from the identification label with the mobile scanner of the stationary terminal. The data about the movement of the strip is transferred to a business application.

Simultaneously with the data transfer on the movement of the strips to a business application, data about the strip, mounted on the uncoiling machine is transmitted to the server trace system Steel Trace Server

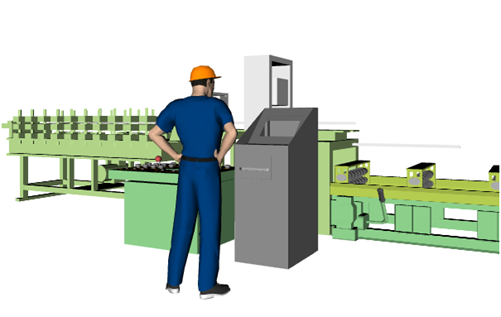

The operator starts the strip mill into production. On the stationary terminal installed next to the mill on the technological scheme the preset sizes of the installed tape come out.

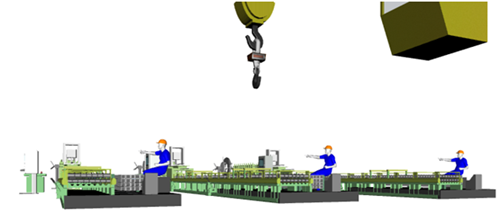

The welding mills are usually quite long (20-30 meters). For this reason the packing process is monitored by a certain worker - packer. For the packers we recommend to create a separate workplace. Packer’s workplace will guarantee the weighting of the package and printing of the expedite tag.

The following image demonstrates the packer’s workplace:

Packer forms and creates the pipe packages. When the package is ready the packer secures it with straps.

On the cranes used in the packaging zone, we recommend to set weighting complex equipment. The weighting complex equipment consists of an additional radio-channel plate for the crane scales and a transponder device "crane-repeater" installed directly on the crane.

As the crane is used for weighing on several sites, in order to avoid mix-weight the packer "captures" the weight, pressing the button all the way down on the weighing device. After pressing the button the weight of the crane scale is shown on the digital display of the device.

Once the package has been stabilized, and the weight is recorded the packer presses the second button which prints the expedite tag.

The proposed scheme involves the automatic defining of crane scales location. For this purpose, we plan to equip the cranes with devices defining the crane position in the plane of the motion axis. This scheme would allow to "capture" not all the scales in the department, but only those which are in a specific packing area.

Packer, pressing the scale "capture" button is connected to the weight of the crane, which is currently in his area of packaging, in such a way, the mill packers located in adjacent bays can capture another crane, regardless of the weighing of other bays.

The fact of printing the label represents for the system the handing over the package. Within the project it is planned to develop regulations under which the package without the tag can not be moved around the plant or outside its premises.

The print time of the label will be fixed in the system and will allow to calculate labor costs for production and packing of the package.

During the formation of the next package the operator is repeating this operation as long as the strip is not finished or is not removed from the uncoiling machine.

When all the packages are ready, the operator completes the rolling of the strip (registering that on the stationary terminal). If there is another strip in the task, he scans the tag of the next strip. If not - he completes the operation.

Accounting of the finished products is done according to the theoretical weight. In case of rolling nonconforming product, it’s weighed and accounted at its actual weight received from the crane scales.

We recommend the package labeling method.