Steel trace system enables increasing the effectiveness of steelworks and mini-factories under conditions of unsustainable consumer demand and high cost of scrap and ferrous alloys.

Steel Trace includes process of charge preparation and preliminary control of chemical composition of the charge. Traceability of charge materials allows to maintain the specified parameters more precisely and to receive information about deviations in advance. The quality of charge preparation considerably influences total reduction of costs and decreases the usage rate of expensive ferrous alloys.

Steel trace system is applied in steel industry in order to control the movement of ferrous materials, preparation and drawing back of charge, accounting of the billets’ movement and loading of equipment in the department.

Containers and big bags with ferrous materials enter MTS warehouse where they are used. When being applied containers and big bags should be labeled with identification tag, containing weight, model of ferrous material, supplier etc. In order to fulfill this operation, we suggest to install a stationary terminal at the MTS warehouse. The stockman of the warehouse chooses the position to be used on the screen and forms the identification label for it.

For marking of containers and big bags we offer to use vinyl adhesive tags S+T GRAPHIPLAST 7377. Tags GRAPHIPLAST 7377 are developed specially for functioning in harsh industrial conditions. They have high temperature stability (operating temperature range -60 - +250 C), high resistance to aggressive chemical environments and mechanical stress.

During the movement of containers and big bags from MTS warehouse to the ferrous material storage bin in the charge-holding bay of the steelmaking department, the stockman scans the bar code from the container label. The stockman of the storage section of the charge-holding bay registers the arrival of containers to the storage bin, scanning bar codes from the identification labels and introduces them into the mobile terminal.

When releasing ferrous materials to the storage area before the electric arc furnace, the stockman indicates in the mobile terminal which containers will be released from the storage bin and scans bar codes from their labels.

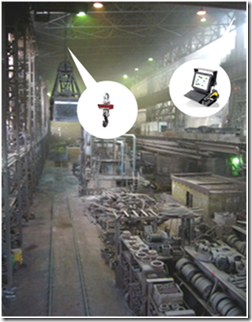

We suggest to provide the crane, removing containers with ferrous materials to the storage area, with the complex “Smart crane”. At the moment of scanning bar codes of the container, the command on its movement is transmitted to the relative terminal; in the process of its movement the container is weighed by means of the crane electronic scales; the data is transmitted to the trace system.

On the admission of containers to the storage area, they are registered in the trace system. For this purpose we suggest to provide the staff responsible for the container storage area with a mobile terminal. On the formation of the charge for melting the bar code is scanned on the container frоm which ferrous materials are being uncharged, after that the necessary amount of ferrous materials is weighed with the scales installed on the platform. The data on the weight of ferrous materials and bar codes is transmitted to the trace system.

In case the bar code is not scanned from the label before weighing or in case the scanning of the bar code is not followed by weighing, a warning appears in the system notifying of the incorrect operation process. For additional control of the release operation of ferrous materials, the storage area is being equipped with the video monitoring system that registers all the operations in the area.

The stocked charge is placed into the mold of the charging machine. We suggest to mark all the molds by individual identification labels in order to provide additional control over the movement of ferrous materials. For marking molds we offer to use high temperature adhesive labels PERMALABEL. Metal adhesive labels PERMALABEL are developed specially for the identification of equipment in iron and steel industry. They differ in high wear resistance, resistance to mechanical stress, abrasion and extremely high temperatures for a long time (PERMALABEL resists the temperature of 1200 °C during 10 minutes, 860°C during 96 hours).

When charging weighed ferrous materials into the mold of the charging machine, the identification bar code on the mold will be scanned, thus we will be informed which mold is charged with ferrous materials. Before charging, the mold should pass test weighing with the platform scales, before weighing the identification code of the mold is scanned and introduced into the trace system. When charging is finished, the charged mold is re-weighed with the platform scales, and at the same time the identification code is scanned again.

In order to control charging of ferrous materials into the furnace, we offer to install video monitoring system on the charging machine on the base of the industrial video camera Lenox Pultz.

Video system Lenox Pultz is designed to control operational processes of metallurgical production under conditions of extremely high temperatures, the working unite of the system can function under the temperature of 2450 °C, receiving at the same time quality-assured video image on the screen of the operator.

Due to the installation of the video system Lenox Pultz on the charging machine you can observe the process of charging ferrous materials from the very beginning up to the end and receive the confirmation of charging to the furnace. The information about the process of charging is shown on the screen of the TWS master and compared to the data from the trace system – the list of ferrous materials in the charge that entered the mold of the charging machine, the weight of an empty mold and the weight of a loaded mold before charging.

In our opinion, the approaches mentioned above allow to provide complete movement trace of ferrous materials from the moment of their start from TWS warehouse up to the furnace charging.

Preparation of the charge buckets for steelmaking is carried out in the drop-hammer plant. We offer to mark every bucket with the identification label PERMALABEL. When filling the bucket in the drop-hammer plant, the charge is weighed with the system «Smart crane», the slinger scans the identification code of the bucket with the charge. The following information about the buckets appears in the trace system: which buckets (numbers) enter the charge section of the steelmaking department, how much the certain charge weighs and what is its composition.

All the information is being traced in the melting sections (probably, customers’ orders). After the buckets having been transported to the crane trestle, they are weighed with the platform scales and when the bucket is risen for charging, its identification number is scanned from the bar code. At the same time the additional weighing of the bucket is realized with the “Smart Crane”. As a result, TWS master (TWS manager) has an access to the full information on the furnace charging – actual control of the charging process in the melting sections, charge composition, weigh.

While moving the ladle with metal, after completing melting process, it is weighed on the secondary refining installation, i.e.we receive data of the metal weigh in every melting section. SCADA-system provides us with the information about the exact melting time and energy consumption during melting process. We also can trace start and end time of the secondary refining process for more accurate cost estimation.

In order to trace the movement of billets to the mold after casting we suggest to use the system «Smart crane», marking and identification system for billets by means of Hot Tag identification labels.

For forming identification labels we suggest to install a stationary terminal in TWS. According to the database of the mold list of casting composition the staff forms on the terminal the Hot Tag identification label with details of the order, cast number, steel model and mold number. After casting the metal into the mold, the label is fixed on the containers of the finished goods.

When moving the container to the carriage for further transporting to the rumbling section, the foreman is forming the movement task on the mobile terminal firstly identifying code from the label on the billet by the bar code scanner. The task formed is transmitted to the terminal of the “Smart crane” complex. While moving the container to the carriage, it is weighed with the crane electronic scales of the “Smart crane” complex. The completion of the operation is confirmed by pressing the sensor screen by the hoister.

Thus, for every movement operation the system registers the identification number of the container, the weigh of the goods, start and end time of the movement, moving route.